- Policies & Forms

- Inner Tube Tips

1. TUBE FAILURES AT THE TIRE BEAD TOE OF AGRICULTURAL TIRES.

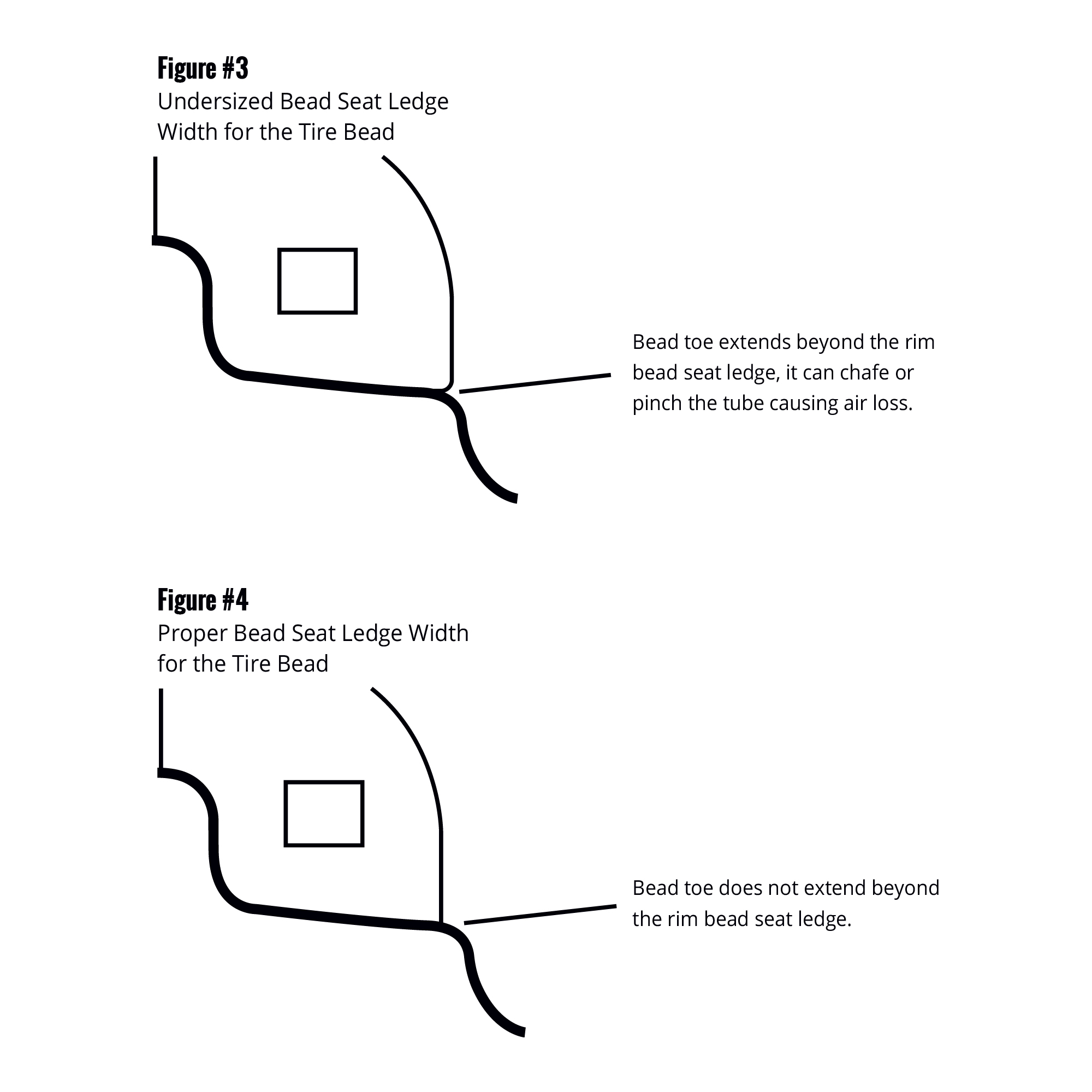

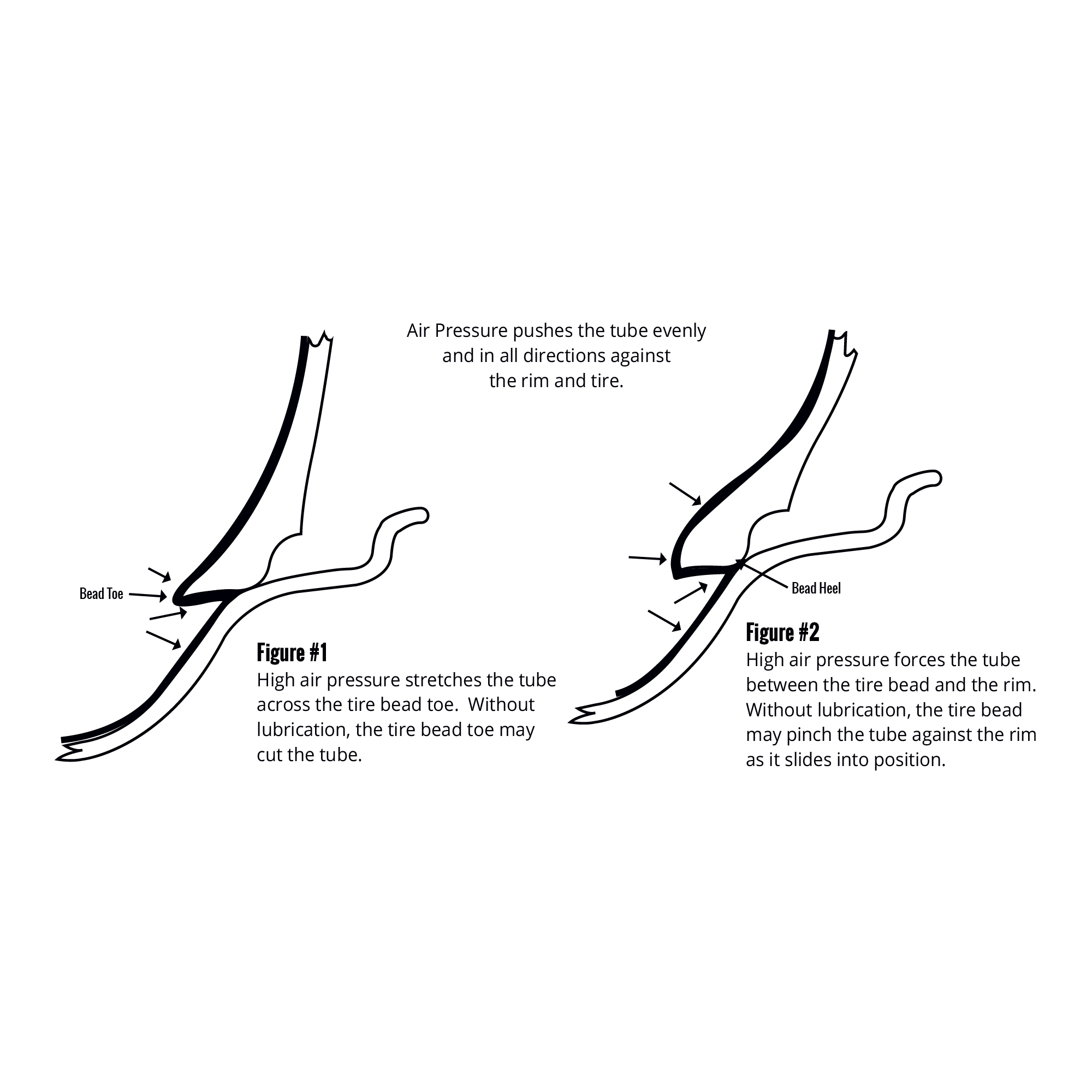

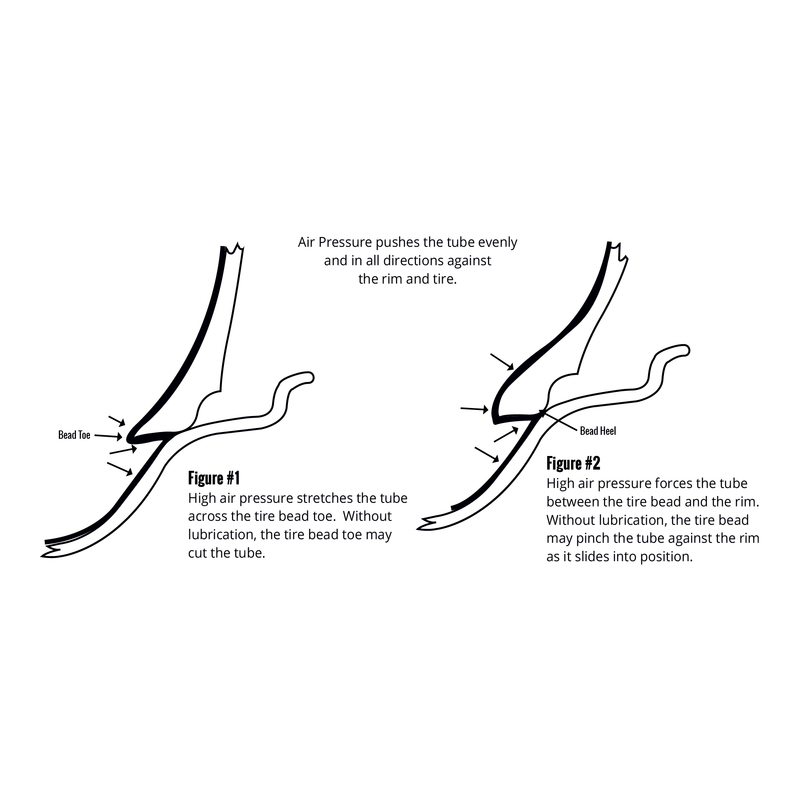

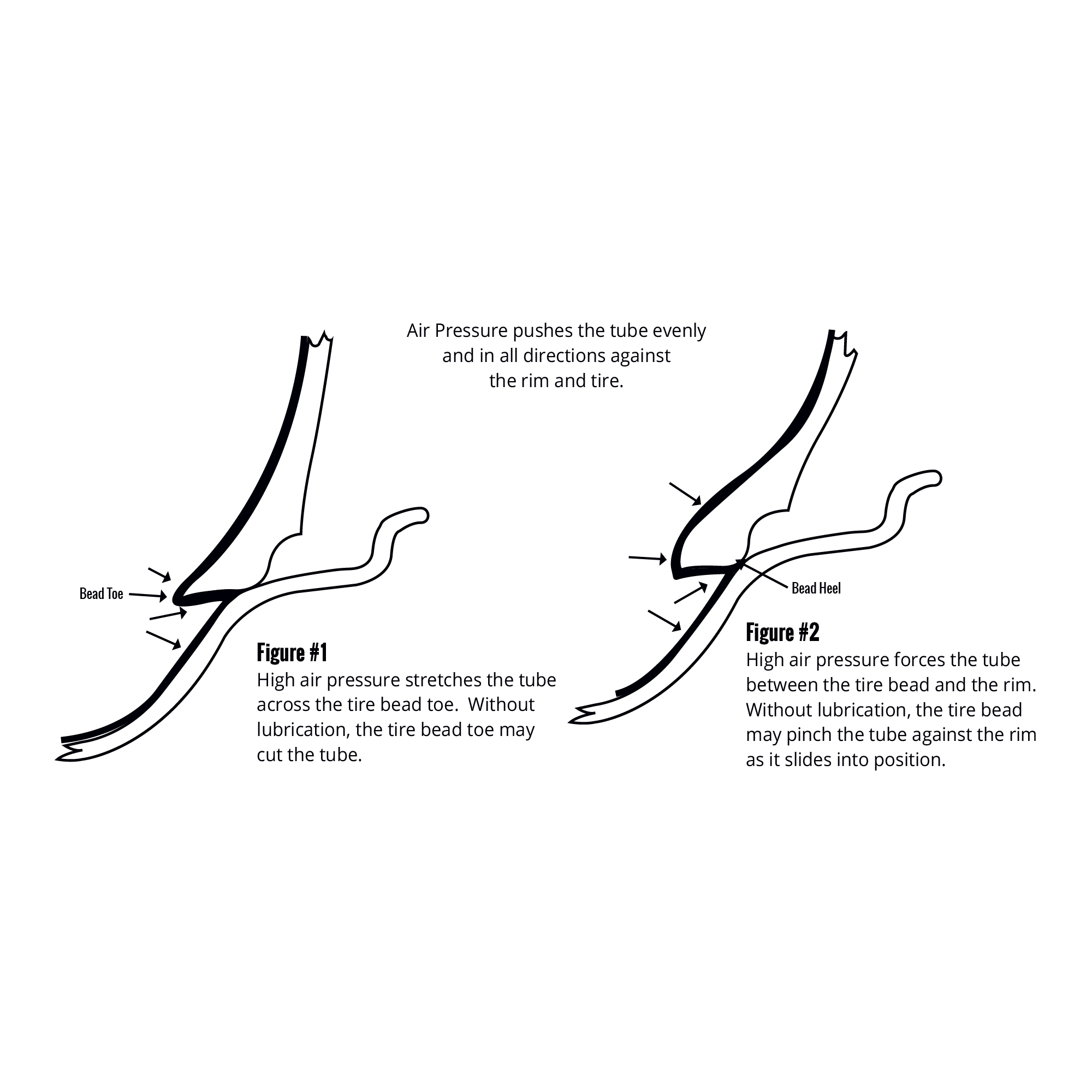

Inspection of tire/tube/wheel assemblies involved in tube failures from bead toe chafing/cutting has revealed that the problem usually occurs during inflation to seat the tire beads and is aggravated by high bead seating pressures, in two situations:

The tube is being cut by the tire bead toe during inflation to seat the tire beads. (See figure #1).

The tube is being pinched between the tire bead heel and the rim during inflation to seat the tire beads. (See figure #2).

Applying a liberal amount of tire mounting lubricant to the (1) rim bead seats, (2) tire beads and (3) tube where it contacts the rim and tire beads will alleviate the problem. Use a vegetable based lubricant diluted 50% with water.

2. REAR TRACTOR/ FORESTRY TUBE INSTALLATION

Field experience has shown that tubes sometimes do not "adjust" well to the inside contour of the tire because the tube surface does not always slip when in contact with a tire that has little or no inside lubrication. This is the reason for industry recommendations to "inflate, deflate, reinflate."

This condition is more pronounced in natural rubber tubes and, as in butyl tubes, may cause folding, tearing or excessive stress on the valve.

It is recommended that natural rubber tubes be lubricated before mounting in addition to the inflate, deflate, reinflate cycle. This assures that the tube can adjust to the shape and contour of the tire/rim envelope. As a minimum, the inside (rim side) and the sidewalls should be lightly lubricated with an approved mounting lubricant. An acceptable and easily applied substitute is oil soap available in spray bottles for home use. It can be diluted 50% with tap water.

Proper lubrication along with the inflate, deflate, reinflate cycle should eliminate or substantially reduce damage to the tube during the mounting operation.

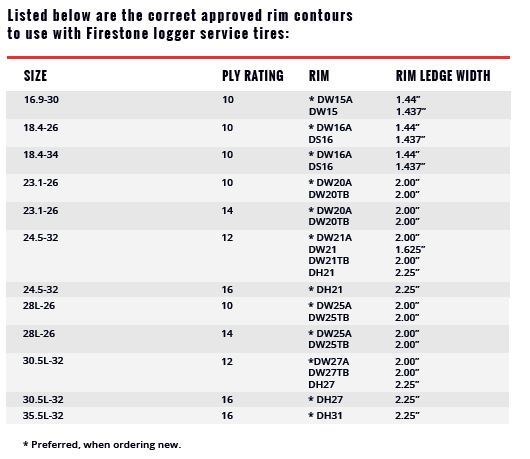

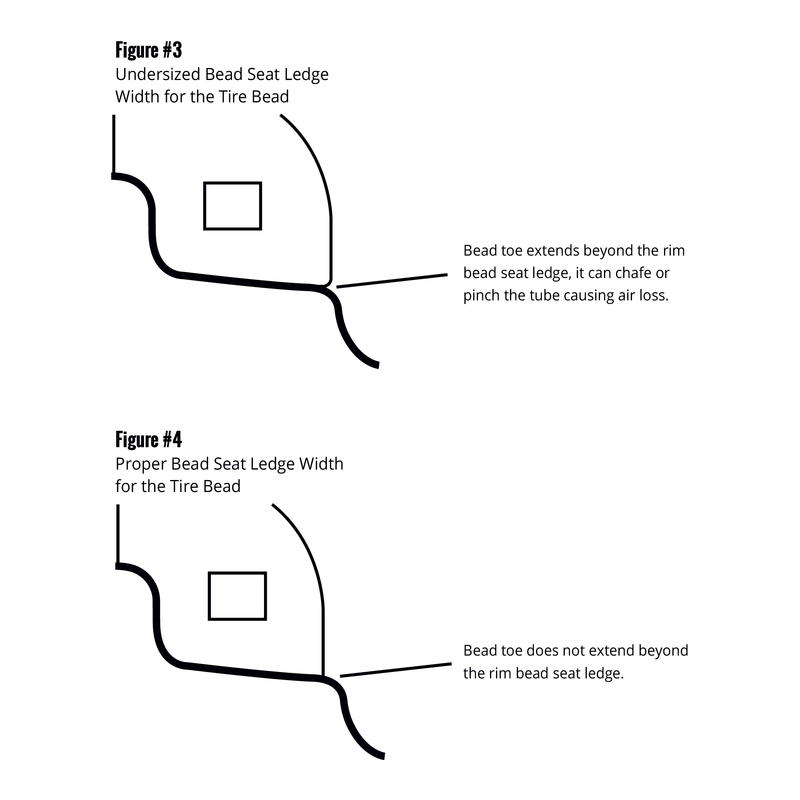

3. LOGGER TIRE/RIM USAGE

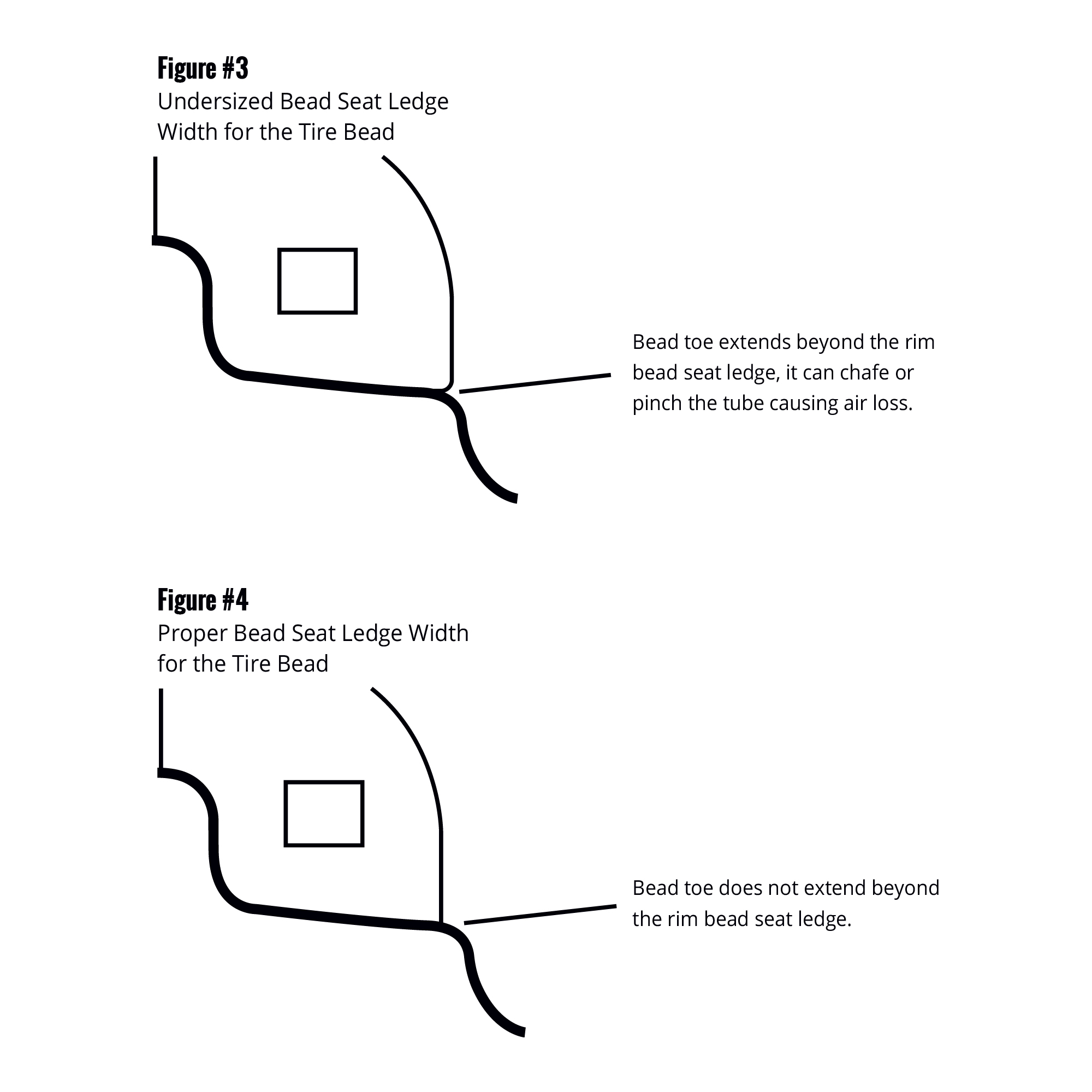

Firestone logger service tires have different bead widths depending on size of tire and ply rating. Rim bead seat ledges must be wide enough to accommodate the entire bead width of a tire for trouble-free service; in some cases, that means a different rim for a particular tire size and ply rating.

Rims with inadequate bead seat ledge width for the tire bead allow the tire bead toe to extend beyond the rim bead seat ledge, which can chafe the tube leading to air loss, downtime and loss of production (see figures 3 & 4).